The challenge of the Fairwood Project facing domestic timber

2021/08/20- text and edit by

- nomlog editorial department

The “Fairwood Project” aims to contribute to the autonomous economic activities of the forestry industry and the protection and growth of Japan's forests by utilizing FairWood (legal and sustainable timber) through the creation of spaces. Therefore, NOMURA GROUP has been working on this since 2018. In this session, we will delve into the outline of the "Fairwood Project" and the perspective of social good obtained there.

This article is a report article of the event "Social Good Week 2021" that introduces the "Social Good" projects of NOMURA GROUP.

* Click here for details on “Social Good”

NOMURA GROUP 's Social Good (Part 1 / Part 2)

* Click here for a list of report articles on “Social Good Week 2021”

Fairwood/Japanese timber utilization project

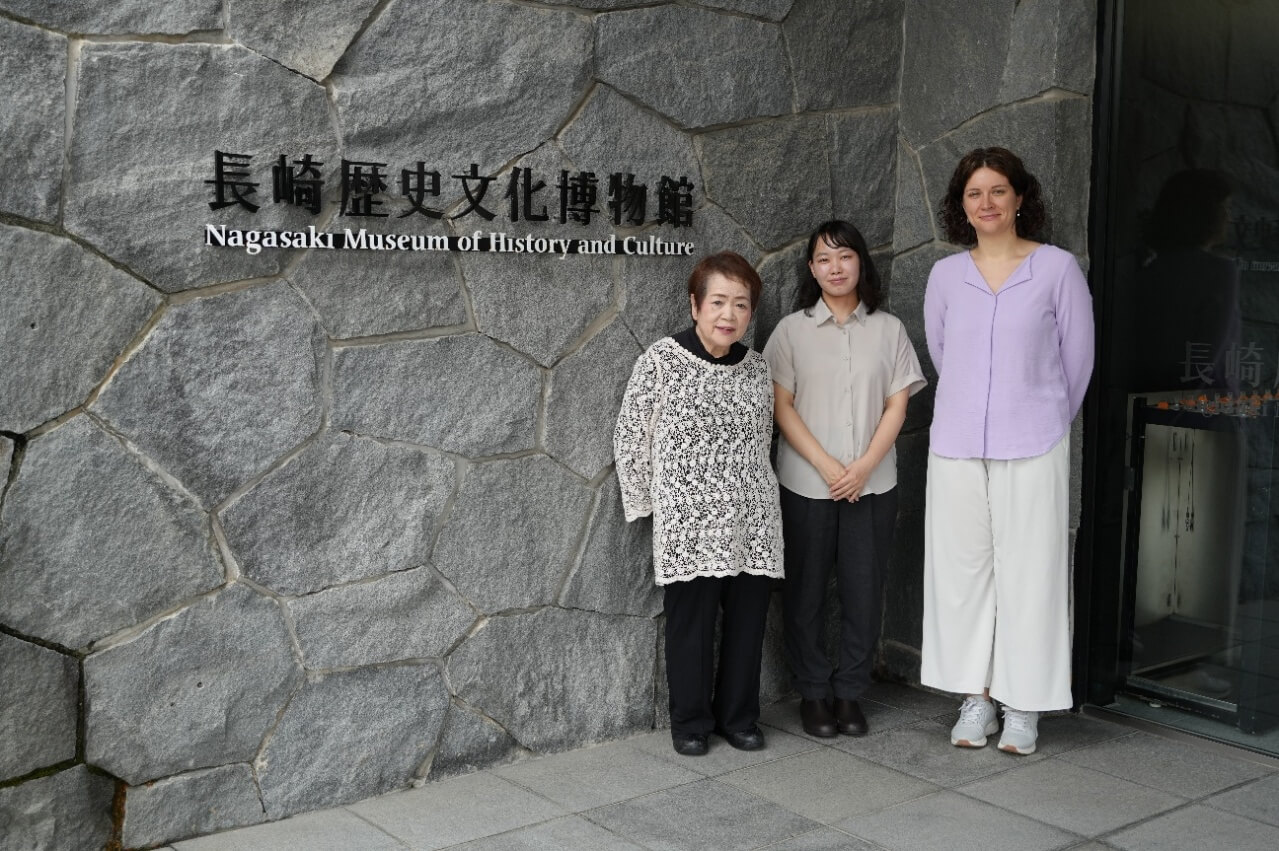

right: NOMURA Co., Ltd. Fairwood Project Leader Goro Kato

He also serves as the leader of the "Fairwood Project" and the "JAPAN VALUE Project", which proposes spaces that incorporate traditional techniques. Through various activities such as organizing tours of production areas, giving seminars, and contributing articles, we aim to create a recycling-oriented wooden space with stories and creativity in wood.

left: NOMURA Co., Ltd. Creative Director/Designer Ryo Onishi

From museum design to corporate showrooms, store design, and workplaces, he has experienced projects that are not restricted to any field. Centering on space creation that fuses the fields of information design and interior design, we are developing creations that comprehensively capture the design process.

Central: NOMURA Co., Ltd., Business Planning Department, Product Division, Nomura Co., Ltd.

Belongs to the Product Division and develops various mechanisms to increase productivity. As part of this, we have started to consider future material procurement by making use of our relationships with partner companies.

Why we choose domestic timber - Japanese timber is now waiting for a new turn

Kato

Fairwood is simply wood with a clear provenance. We focus on reducing, reusing, recycling, and legality by avoiding illegal logging, with timber and timber products that take into account the forest environment of the logging area and the local community. Among them, NOMURA GROUP pays particular attention to domestically produced timber.

There are five reasons to focus on domestic lumber. The first is that now is the time to cut down Japan's forests. The second is that national policies are moving toward the utilization of domestic materials. Third, the story of wood shock*, illegal logging and prices is relevant. Fourth, there is an affinity between NOMURA GROUP and wood distribution, so there are expectations for distribution reforms.

About 70% of Japan's land area is forest, of which about 40% is artificial forest, and about 70% of that artificial forest is cedar and cypress, which were planted on a large scale after the war to support housing demand. More than 51% of the trees have been planted for more than 50 years. However, in Japan, the number of wooden houses is decreasing, and there is a tendency not to use wood itself, so the current situation is that we are not making the most of our abundant resources.

Japan's forests, where more than half of the trees are over 50 years old, are about to be felled

Japan's forests, where more than half of the trees are over 50 years old, are about to be felled

What is Woodshock

It refers to the soaring import timber prices that started around March 2021. Due to multiple factors, such as the rapid increase in the demand for timber for new housing in the United States and China, and the worldwide shortage of shipping containers, it has become difficult to obtain imported timber, especially for pillars and beams, and prices are soaring. This is a big problem for Japan, which depends on imports for more than 60% of its lumber.

On the other hand, in 2019, a forest environment transfer tax was established. Basically, it is money for growing forests and is given to local governments. Urban municipalities that do not have forests can use them to promote the use of wood. By the way, in the past, wood was mainly used for housing, but as the population is declining, there is a limit to demand for housing.

And while there is a social issue called "wood shock" where SPF materials and laminated wood of American pine are in short supply, in our industry, it is becoming difficult to obtain lauan materials used for plywood. Some view the Wood Shock as a temporary event due to logistics issues, but Japan's deflationary situation may be prolonged due to its weak global price competitiveness. Also, it is difficult to ensure the traceability of lauan wood, and the risk of illegal logging is high, so we would like to take this opportunity to promote the use of domestic wood. If we use timber cut in Japan instead of foreign timber, we can reduce the burden of transportation.

And in terms of how NOMURA GROUP can coordinate with the logistics system, if you want to use it only once and create originality while making use of the existing distribution system, you can directly connect with the production area. Wood that has not been distributed can also be used with high value. By using a wide variety of domestic timber, we can create demand on the mountain side and contribute to a large forest cycle that spans more than 100 years by cutting, leveling, planting, and growing.

By directly connecting with the production area, it is possible to utilize timber that is not normally distributed.

By directly connecting with the production area, it is possible to utilize timber that is not normally distributed.

By using wood on the city side, the economy on the mountain side will also go around.

By using wood on the city side, the economy on the mountain side will also go around.

Designer's use of wood - designing not only space but also process

Kato

From here on, I will introduce examples of the "Fairwood Project" in chronological order, starting with Onishi.

Onishi

The first project I would like to introduce is a project that maximizes the use of wood as a material. This is a case from a while ago, but it is "3×3 Lab Future" which we worked on together with our designer, Echiyo Suzuki. Here, we used a lot of rare species of timber instead of commercially available timber, and digitized the timber with captions. There is also a VIP room that introduces the Itakura construction method, a traditional Japanese wooden construction method, and a reception counter designed to make the most of the cross-section of Owase incense cedar, which has a strong scent. We created a space by making the most of the properties of wood, and worked on turning materials into information media in order to appeal the richness of wood.

A wooden door made from over 20 rare species of wood.

A wooden door made from over 20 rare species of wood.

A counter made of Owase incense cedar that welcomes you with the scent of wood

A counter made of Owase incense cedar that welcomes you with the scent of wood

The next example is the Kanda Myojin Cultural Center "EDDOCCO" project, which conveys the entire use of wood as a "story". With a subsidy from the Project to Promote Timbers Produced in Tama, which stands out in bustling facilities, the interior design uses Tama timbers to create a shrine-like design. Kanda Myojin enshrines Daikoku-sama, Ebisu-sama, and Taira no Masakado, but there are many Masakado legends in the Tama area, which is the production area of Tama wood. Masakadogahara, Masakado Falls, Masakado Shrine... In fact, Tama was a land deeply connected to Kanda Myojin. Therefore, I made this connection into a "story" and asked the priest to be the storyteller and tell it. In addition to the space design, I designed the process of spreading Tama materials through the chain of symbolizing Kanda Myojin, memorizing it, and writing the "story" into an article.

A sales space on the first floor that uses plenty of Tama materials

A sales space on the first floor that uses plenty of Tama materials

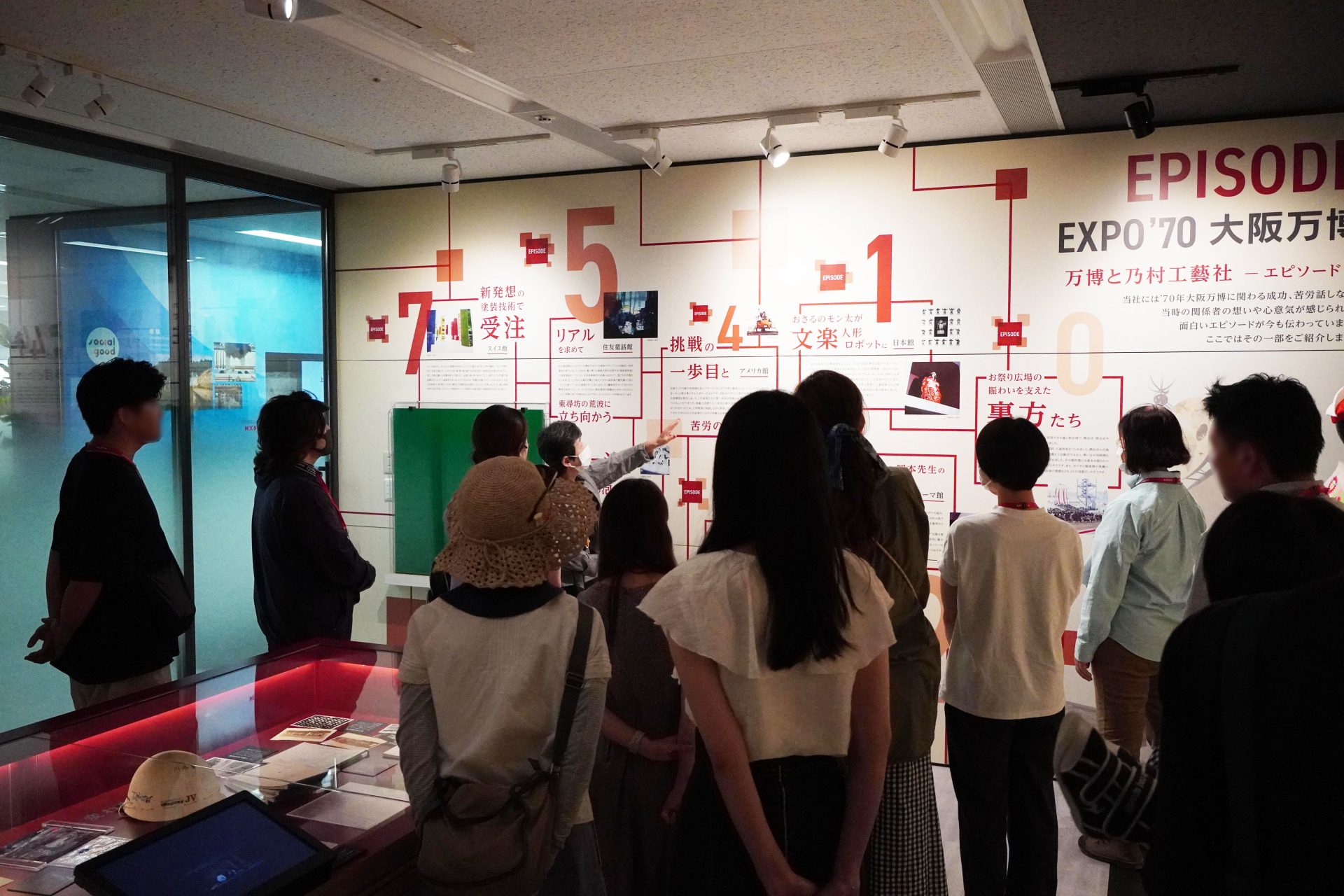

These two projects were my own projects, but at the same time, they also gave me the opportunity to change my own perception. Another trigger was the Forestry Agency subsidized project MORIMACHI Door 's "production area experience event" that our company worked on. At first, I felt like I was on an excursion, but as I met and listened directly to people who saw lumber and felled trees in the mountains, I learned about the distribution process of timber: upstream, midstream, and downstream. It was an opportunity to think about how we should use wood in this process. At the same time, I was able to realize once again that my involvement in my work is downstream.

Onishi participated in MORIMACHI door production area experience event, which visited three production areas, in Tama and Owase.

Onishi participated in MORIMACHI door production area experience event, which visited three production areas, in Tama and Owase.

The "PARA HEROes Exhibition", which uses para table tennis as its theme, is an attempt to design not only the use of wood, but also the process of creating a sustainable structure. Normally, wreath panels are used for exhibitions that are held for a limited period of time. However, this time, we worked to realize sustainability by not only making the panels wood, but also unitizing them so that they can be reused and eventually recycled. In addition, we used a box horse as an exhibition stand so that it can be reused even after the exhibition. Disposable warping paper is usually used for the base of the walls where the paintings are displayed, but here we use canvas, which can be peeled off cleanly after the exhibition and can be used by artists for oil paintings. I made it

When I conveyed these thoughts to the carpenters who set up the tree, I felt that the way they touched the wood became gentler. I realized that this might be a hint for spreading ideas through design. It's important to jump in and tell everyone, but first, to those close to us downstream. From there, I felt that it was important to convey the message to people a little upstream.

"PARA HEROes Exhibition" Challenges the Sustainability of Exhibitions

"PARA HEROes Exhibition" Challenges the Sustainability of Exhibitions

From the standpoint of making - Fairwood Project, a joint effort

Kato

I believe that the future role of design will be how to use limited resources.

From here, I would like to introduce what Obana is doing on the production side of our company.

Obana

I'm Obana from the Business Planning Department of the Product Division. As a member of the Product Division, which is responsible for manufacturing, I am now able to be involved in this Fairwood initiative.

The Product Division is responsible for the front line of manufacturing, from planning related to construction to on-site management. However, we do not have a factory where we can manufacture our own products. Therefore, we are building a production system together with many cooperating companies. Therefore, our company alone cannot achieve 100% domestically produced timber, so we would like to work together with our partner companies to work on Fair Wood.

With regard to the current topic of wood shock, I feel a great sense of crisis regarding the maintenance of the production system related to timber. Depending on the type of wood, the price is 2.5 times higher than before the corona disaster. The media is talking about laminated timber for housing, but lauan, which is often used in our industry, is becoming difficult to obtain. This critical situation has made me think again about what Fairwood is. I'm beginning to think that we should think concretely about making more use of domestic lumber and work on it.

In the future, we would like to promote forestry experiences and exchanges with domestic timber production areas for our partner companies. The CSV Committee of the Nomura Cooperative Association is prototyping 100% Fairwood fixtures. We would like to share the meaning and significance of being FairWood with our partner companies and explore the possibility of using 100% domestic wood together.

100% domestically produced wood fixtures prototyped by the CSV Committee of the Nomura Cooperation Association (lower right)

100% domestically produced wood fixtures prototyped by the CSV Committee of the Nomura Cooperation Association (lower right)

Enriching business, society, and the environment with Fairwood spatial design

Kato

thank you. Finally, as a summary, a word from each of you.

Obana

There are thousands of construction partner companies in NOMURA GROUP, and it may be difficult to start working on Fairwood right now or change your mindset, but I would like to ask all of you to have that mindset, even if just a little. I would like to create an environment where we can work on fair wood step by step.

Onishi

I think this kind of meeting is really important. There are still many things that are lacking, but I would like to make the use of Fairwood a matter of course as soon as possible, and I would like to think about the next step by quickly grasping the trends of the world.

Kato

NOMURA GROUP 's Fairwood Project not only improves business feasibility through space design that makes use of domestic timber, but also contributes to social and environmental benefits such as economic circulation to local communities and forest conservation in the production process. It is a project that produces the effect of

Finally, I would like to talk about four things that I would like to work on from the perspective of social good.

The first is to be conscious of increasing the use of wood itself. Second, to effectively introduce solid wood with pinpoint accuracy. Third, verify that domestically produced veneer can be used, and switch to domestically produced veneer as much as possible. Fourth, think about whether it is possible to change to wood where metal and plastic have been used until now, and take on the challenge.

Thank you for your attention.

NOMURA GROUP has various creators involved in space creation, such as designers, planners, and products. First of all, from each standpoint, each person is conscious of fair wood and domestic wood as materials. We know that actively using them will lead to a rich environment and a recycling-oriented society. And with various ideas, I challenge to create a space. Through this session, we were able to share once again that social good begins with a change in the mindset of each employee. Please look forward to the future activities of the Fairwood Project. (nomlog editorial department)

Text: Sho Iwasaki/Photo: Yui Yasuda (during the event)

[Articles related to the Fairwood Project]

The entrance to co-creation that nurtures the forest “MORIMACHI Door” project

"Morimachi Door" -- Work with people in the forest

Like this article?